I'm going to start building the coffee table soon. But first, I have to put away a ton of stuff that has accumulated in the shop in the almost 2 years since I finished building the pulpit.

In 2009, I created a post on WoodNet's Off Topic forum descrying my lack of funds for doing woodworking. I had all this free ime on my hands but couldn't afford to buy any wood to make anything. In addition, I had bought a Rikon Mini Lathe 3 weeks before I was layed off from my job and I didn't have any turning tools Lathes, drills, and routers are all alike in that the tool by itself isn't much good without the accessories, after all!

Much to my surprise & gratitude, the guys on WoodNet rallied & sent me about 70 bd ft of quarter sawn red oak and 6 or so different turning chisels and a number of other turning tools, like a pen mandrel and other things for making pens. I really don't know what all of the tools I was sent are called; I'm going to have to spend some time researching it.

So I went into the shop today & cleaned the dirt off of the table saw top that had accumulated & began putting things away. Then it hit me: I have no where to put the turning tools, and a lot of the clutter on my "bench" / temporary work table is the turning stuff.

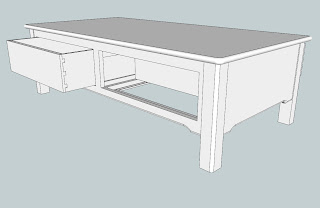

So after I finished cleaning the tablesaw & spraying on a new coat of T9, I sat down with SketchUp & whipped up the drawing at the right.

The whole thing will be made from scraps of plywood I have left over from my previous projects. The whole thing stands about 30" tall and is 19 1/2" wide. The inside width is 18".

The 6 chisels I have, plus the roughing gouge & spindle gouge I bought a few months ago will be stored in the upper area. leaning back against the ribbed strip at the top. There's a 1/2" tall lip attached to the front of the shelf to keep the bottoms of the turning tools from sliding off of the shelf. The handles of my tools are all about 1 3/4" in diameter at their widest points, so I alloted 2" of width for each one. There will be room for a couple more gouges once I've got my existing tools in it.

I'll store the pen mandrel and other turning related stuff that isn't a gouge or chisel in the drawer. The drawer has through dovetails front & back. The front, back & sides will be made from 1/2" solid wood. It's about 4" tall & 5" deep. I thought about making 2 drawers & I may do that in the end. An 18' wide drawer may be a little unweildy.

The cabinet will be mounted to the wall using some screws. One day, I hope to replace the shelves on the walls with a bunch of french cleats & make cabinets & other tool holders to mount to them. I will turn this into a french cleat mount at that time.

I'm going to make a simple board with 3 pegs for hanging up extension cords, too, but that is too simple a project to show. It will just be 1 piece of 3/4" poplar 2" tall & 32" wide with 3 1/2" diameter dowels 7" long sticking out of it at a 15 degree angle. The pegs will mounted on 14" centers. That way I can get my extension cords out of drawers & hanging on the wall. Then I can put other stuff away.